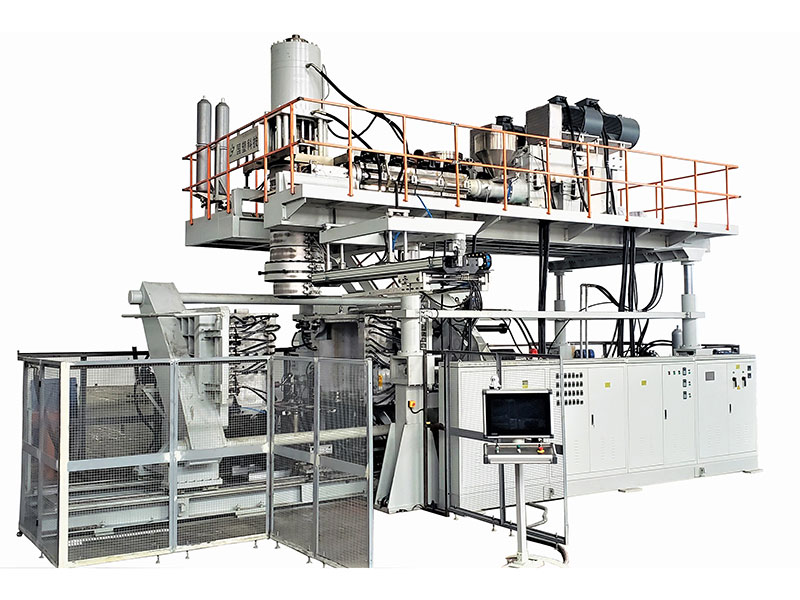

HBD40 Single Station Blow Molding Machine

KB2000L/IBC tankblow molding machine is specially used to produce single and double & Three-layer IBC tank. Its production capacity is 14-15 kg, 185 seconds per tank. This machine is equipped with 120 30:1 polymer screw and frequency conversion motor. The screw part is equipped with two sets of pressure sensors and a 50L double& Three-layer accumulator die-head. Servo Hydraulic Drive ( Rexroth ),21-inch imported high-definition touch screen ( From Germany with remote debugging and monitoring).

It can also be used in 220 liters double ring drum production (equipped with multiple sets of procedures and corresponding down-blowing device). We are a professional blow molding machine manufacturer. We always focus on blow molding.

| Specifications | Units | KB2000L/IBC Single layer | KB2000L/IBC Double layer | KB2000L/IBC Three layer |

| Material | HMWHDPE | HMWHDPE | HMWHDPE | |

| Max.Product capacity | L | 2000 | 2000 | 2000 |

| Die quantity | Set | 1 | 1 | 1 |

| Machine dimension | M | 10.9×4.3×7.9 | 10.9×4.3×7.9 | 10.9×4.3×7.9 |

| Machine weight | Ton | 50 | 55 | 60 |

| Clamping Unit | ||||

| Clamping force | KN | 1800 | 1800 | 1800 |

| Distance between platens | mm | 1000-3000 | 1000-3000 | 1000-3000 |

| Platen size | mm | 1500×1800 | 1500×1800 | 1500×1800 |

| Power | ||||

| Total power | KW | 420 | 520 | 600 |

| Average energy consumption | KW | 300 | 350 | 400 |

| Hydraulic drive power | KW | 37+7.5 | 37+7.5 | 37+7.5 |

| Air pressure | Mpa | 1.0 | 1.0 | 1.0 |

| Air consumption | m³/min | 5.0 | 5.0 | 5.0 |

| Extruder unit | ||||

| Screw diameter | mm | 150 | 120×2 | 100/120/100 |

| Screw L/D ratio | L/D | 30 | 30 | 30 |

| Plasticising capacity | Kg/hr | 600 | 400×2 | 200/400/200 |

| Quantity of screw heating zone | Zone | 7 | 7+7 | 5+7+5 |

| Extruder heating power | KW | 49 | 42×2 | 24+42+24 |

| Extruder driving power | KW | 160 | 132×2 | 75+132+75 |

| Die-head | ||||

| Quantity of die heating zone | Zone | 8 | 8 | 8 |

| Power of die heating | KW | 56 | 56 | 56 |

| Max.diameter of die | mm | 800 | 800 | 800 |

| Accumulator capacity | L | 40 | 50 | 50 |

Fill out my online form.